LIGNIN AS FEEDSTOCK FOR BIOAROMATICS

The road from huge potential to first applications

Aromatics are one of the main building blocks for today's chemical industry. Currently, virtually all these blocks are made from fossil oil, but because of increasing scarcity, replacement by alternative feedstocks is highly needed. The potential of lignin in this matter is huge, but largely underexploited. Throughout different projects and together with national and international partners, VITO aims to bring biobased aromatics closer to industry.

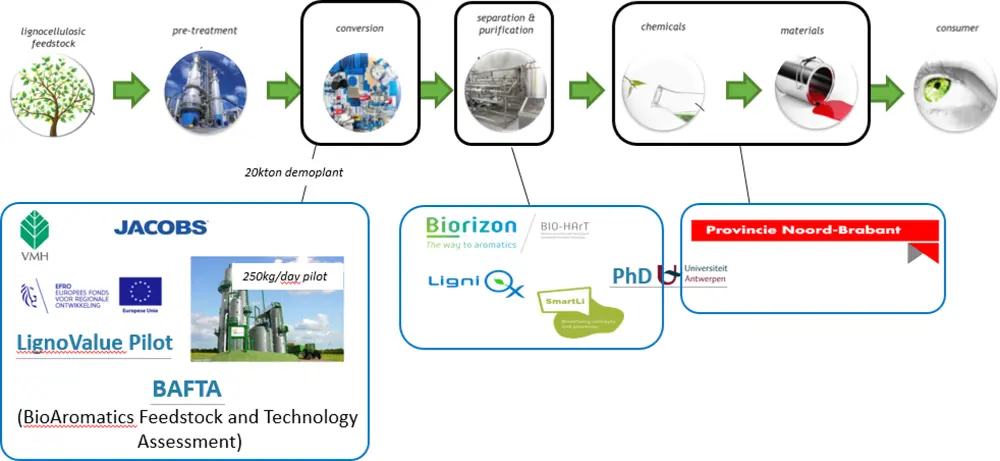

Biorizon consortium

Within the Biorizon consortium, TNO-EnergieTransitie (TNO-ET) in Petten, the Flemish Institution for Technological Research (VITO) in Mol, and the Dutch Organisation for Applied Natural Scientific Research (TNO) in Delft each research a different pathway to get from lignin and carbohydrates to functional aromatics. A Biorizon road map is aimed at three horizons:

• A lignin horizon: obtaining functional aromatic building blocks via depolymerisation and fractionation.

(This article - published in NPT 19-01, March 2019, p.21-23),

• A sugar horizon: production of functional aromatics obtained through Diels Alder

(Read 'Utilization of waste sugars for functionalized bioaromatics' - published in NPT 19-02, May 2019, p.10-12) en

• A thermochemical horizon: production of non-functional and functional aromatics

(Read 'Pilot zet lignine om in diverse aromatische verbindingen' - published in NPT 20-02, June 2020, p 11-12).

At the Green Chemistry Campus - located at the SABIC site in Bergen op Zoom - the consortium partners are testing these new pathways. Other knowledge institutes, research institutes and companies are also testing new sustainable technology there with the support of the Province of North Brabant, the municipality of Bergen op Zoom, SABIC and the regional development company NV REWIN West-Brabant.

POTENTIAL OF LIGNIN UNDERUSED

The European chemical industry may grow, but globally it loses market share due to the strong growth in emerging countries and loss of competitiveness. In order to reverse this trend, the sector wants to bring new, innovative and more sustainable products and processes onto the market by the replacement of fossil based and toxic products by biobased, performant, safe (less toxic) alternatives. Nowadays, the European chemical industry is using 47 million tonnes of carbon per year, all coming from fossil fuels, while European forests have a biomass potential that is 2000 times bigger. Many studies have shown the tremendous potential of lignocellulosic biomass residues (such as wood, straw, corn stover, switch grass, forestry residues including bark as well as waste wood) for the sustainable production of chemicals and fuels, and more specifically biobased aromatics.

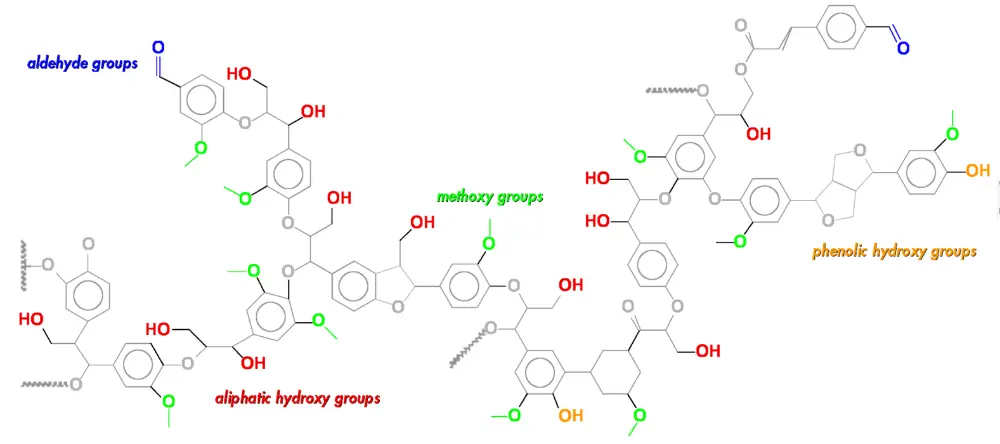

An important component of lignocellulosic biomass is lignin, which is the second most abundant renewable carbon source on Earth. An estimated 60-70 million tonnes of lignin are liberated into different pulping spent liquors in the pulp and paper industry. Currently, more than 95% of this type of lignin is used for energy production (burning). However, through its aromatic structure and functionalities, it exhibits a variety of properties by which it can serve as a renewable feedstock for the production of not only biofuels, but also materials and biobased aromatic specialty chemicals.

Up to now, this potential is largely underexploited, mainly due to the complex structure, heterogeneity and high polydispersity of lignin. In the last decades, progress has been made in different fields in the lignocellulosic value chain, including biomass pretreatment, biomass depolymerization and lignin valorization. Via national and European projects as well as own strategic research VITO is involved in most steps of the wood/lignin-to-aromatics value chain and therefore well placed to play a role in connecting the different parts, which is highly needed to move forward and bring biobased aromatics to a larger scale.

DEPOLYMERIZATION AND FRACTIONATION OF LIGNIN

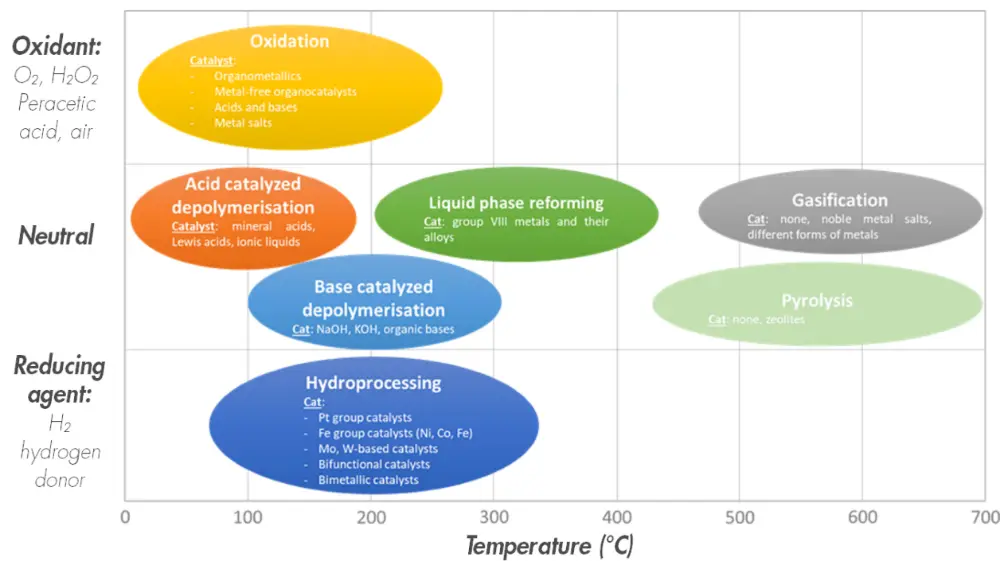

Within the framework of different regional and European projects, VITO is benchmarking various processes that convert wood and lignin into a complex mixture of bio-aromatics. By depolymerization, the complex lignin macromolecule is converted into a mixture of small molecules and oligomers which can be used for further application developments. Since the lack of reactivity is often a drawback in applying lignin as such (as a macromolecule), depolymerization of lignin is used to increase its reactivity by creating new reactive sites.

Diverse processes with varying process conditions, e.g. metal-catalyzed or acid-catalyzed, have been developed, of which many have only been demonstrated at lab scale. Hence, their role and market potential in a biobased economy using lignin as a resource of chemicals and polymers is still unclear.

To tackle these issues, a Catalisti study entitled 'Bio-aromatics Feedstock and Technology Assessment (BAFTA)' has been organized in which VITO and KU Leuven perform a thorough landscape analysis of technologies available all over the world for the direct conversion of wood and the depolymerization of lignin into biobased aromatics, and insights are gained in the most preferential depolymerization technologies based on a number of well-defined criteria (e.g. TRL level, level of sustainability, yield, etc.).

The natural complexity of lignin however makes its depolymerization a challenging task and gives rise to a complex mixture of monomers, dimers and oligomers, requiring downstream separation/fractionation. To enable the application of the lignin-derived mixtures in e.g. polymer applications, these mixtures have to meet the required specifications (reactivity, OH content, molecular weight) for the application under consideration. Hence, tailoring of the lignin oils towards application development is required. In addition, fractionation pretreatments can be applied to produce more homogeneous lignin fractions with reduced polydispersity. Due to the significant complexity of the resulting lignin oils in terms of structure, polarity, functionality and molecular weight, further separation is highly challenging. Due to its strong expertise in separation processes, VITO is also involved in this part of the value chain. Within the project SmartLi - Smart technologies for the conversion of industrial lignins into sustainable materials (Horizon 2020 - BBI, Research and Innovation Action), VITO has been exploring membrane filtration for purification and fractionation of both technical lignins and lignin degradation products, in aqueous as well as organic solvent environments. Furthermore, VITO is also partner in the ongoing demonstration project LigniOx (Horizon 2020 - BBI), where lignin by-products from pulp mills and other biorefineries are being converted into high performance biobased plasticizers for cement and concrete using an oxidation technology developed by VTT. In this project, VITO is developing a membrane separation based post-treatment process to concentrate the oxidized lignin solutions.

FROM LAB- TO PILOT-SCALE

The applicability of the majority of the investigated and developed technologies for the conversion of wood and lignin into biobased aromatics and the subsequent fractionation into useful fractions of lignin-based monomers, dimers and oligomers has already been proven at lab-scale. To maintain the resulting momentum on bio-aromatics in the future, the demonstration of available conversion technologies at relevant scale (TRL 5-6) is the next crucial step, which implies the availability of a pilot line.

This will allow the production of larger amounts of bio-aromatic fractions, as such allowing companies to take further steps in their application development path. A large number of companies already indicated an interest in these innovative molecules and a willingness to carry out the necessary application testing/product development, but often, this can only be done at kg scale (if not 100 kg scale) so that large quantities of bio-aromatic fractions are needed.

To set up this functioning pilot line in Flanders for the production of bioaromatics from lignin/wood, VITO and its partners Jacobs België NV and Flemish Environmental Holding (VMH) have recently launched the EFRO LignoValue Pilot project. The total budget of the project is € 4.3 Mio, with cofinancing from ERDF, the province of Antwerp and the Flemish Department of Economy, Science and Innovation. The LignoValue project is also actively supported by Catalisti, the Flemish spearhead cluster for chemistry and plastics, as it perfectly fits in its strategic research program on bio-aromatics. The investment in and the design and construction of the LignoValue Pilot (EFRO) with a capacity of ca. 200 kg/day input will enable companies to take the necessary steps forward in their application development trajectory. The aim is to design the envisioned pilot line as flexible as possible to demonstrate different depolymerization processes in order to produce the desired bio-aromatic fractions for company-target applications/product development. Setting up this pilot line contributes to the ultimate goal: building and operating a demo plant in Flanders for the conversion of wood/lignin to biobased functionalized aromatics.

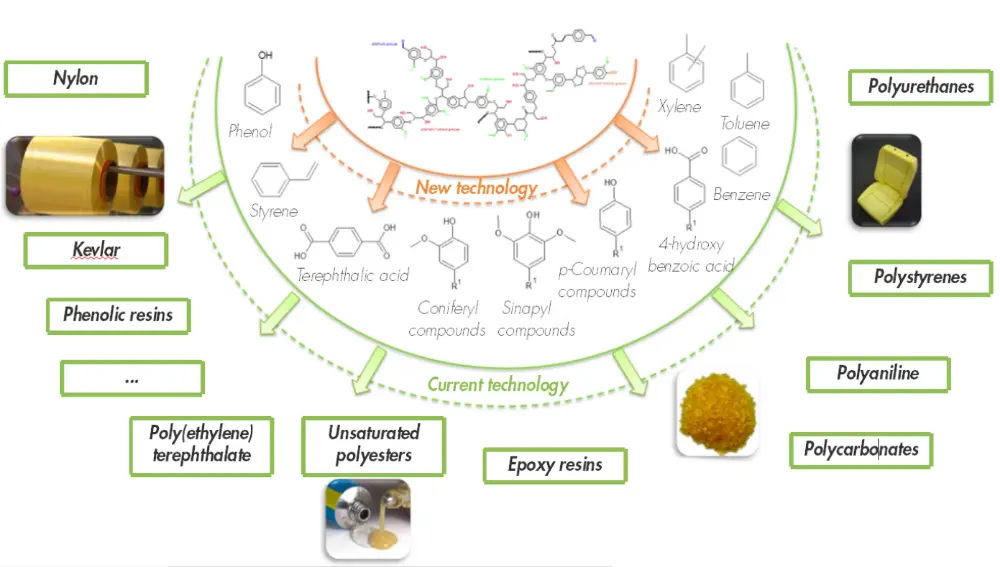

FROM LIGNIN TO PRODUCT: WHICH APPLICATIONS DO WE HAVE IN MIND?

The synthesis of (semi)aromatic polymers derived from renewable resources is currently attracting tremendous interest from both academia and industry, because aromatic compounds are key intermediates in the manufacture of polymers and chemicals. However, the full potential of lignin for production of commodity polymers and additives is underutilized in the polymer industry, mainly due to the difficulty in obtaining aromatic chemicals with the desired functionality. Therefore, not only the valorization of biomass through conversion of lignocellulose into value-added lignin fragments and bio-aromatic derivatives, but also the demonstration of how these building blocks can be polymerized into value-added products is part of VITO's research strategy.

Besides conversion and fractionation, chemical modification technologies are required to functionalize and tune the obtained lignin derivatives into desired functional aromatic building blocks, hence meeting the specifications of the targeted applications in terms of e.g. reactivity. Depending on the specific chemistries involved in the targeted products, different chemical modifications are needed to increase the reactivity of the lignin derivatives and to facilitate their integration in various polymer systems.

The chemical modifications can either rely on:

- (i) directly using the functional groups intrinsically present on the lignin (such as phenolic OH),

- (ii) optimizing the existing functional groups via simple reactions (such as converting phenolic hydroxyl groups into more reactive aliphatic hydroxyl groups, or demethylating bio-aromatic groups into less hindered rings), or

- (iii) by adding totally new functional reactive groups that are not present on lignin (such as epoxy groups or acrylic groups …).

Once these building blocks are available, current technologies can be used for formulation of these compounds into commodity monomers and polymers. Depending on the phenol substrates obtained from the lignin conversion and subsequent fractionation/purification processes, different chemical modifications and polymerization pathways are envisaged and developed in VITO's strategy, leading to (semi)aromatic polymers covering a wide range of industrial applications such as polyurethanes (PU), phenolic resins (PF) or epoxy resins. A joint collaborative postdoc program is established in this field with SCION (New Zealand).

Besides the focus on polymer applications in which lignin-based compounds are used as a polymer building block, the development of lignin-based (polymer) additives, e.g. flame retardants, antioxidants, … to induce specific properties is also considered. In this framework, a PhD study is recently started in collaboration with the University of Antwerp, looking into the development of lignin-based flame retardants by using the dimeric compounds present in various lignin oils.

REFERENCES

- [1] Li, C., et al., Catalytic Transformation of Lignin for the Production of Chemicals and Fuels. Chemical Reviews, 2015. 115(21): p. 11559-11624.

- [2] Isikgor, F.H. and C.R. Becer, Lignocellulosic biomass: a sustainable platform for the production of biobased chemicals and polymers. Polymer Chemistry, 2015. 6(25): p. 4497-4559.

ACKNOWLEDGEMENTS:

VITO likes to acknowledge the province of Noord-Brabant (The Netherlands) for financial support in the framework of the activities at the Shared Research Center Biorizon and all partners from the running projects, including BAFTA, BIO-HArT, SmartLi, LigniOx and EFRO LignoValue Pilot.

The project SmartLi - Smart Technologies for the Conversion of Industrial Lignins into Sustainable Materials (2015-18) has received funding from the Bio Based Industries Joint Undertaking (BBI JU) under the European Union's Horizon 2020 research and innovation programme under grant agreement No 668467.

The project LigniOx - Lignin Oxidation Technology for Versatile Lignin Dispersants (2017-21) receives funding from the Bio Based Industries Joint Undertaking (BBI JU) under the European Union's Horizon 2020 research and innovation programme under grant agreement No 745246.

BIO-HArT is established by a contribution of the European Interreg V Flanders-The Netherlands program that stimulates innovation, sustainable energy, a healthy environment and the labor market by means of cross-border projects.

The work within the BAFTA project is performed within the Catalisti cluster, with the financial support of VLAIO (Flemish Agency for Innovation and Entrepreneurship).

For the LignoValue Pilot project we acknowledge the financial support of the European Regional Development Fund (ERDF), the province of Antwerp and the Flemish Department of Economy, Science and Innovation.