electrochemical production of bio-based chemicals

EU Perform project shows potential of large scale production

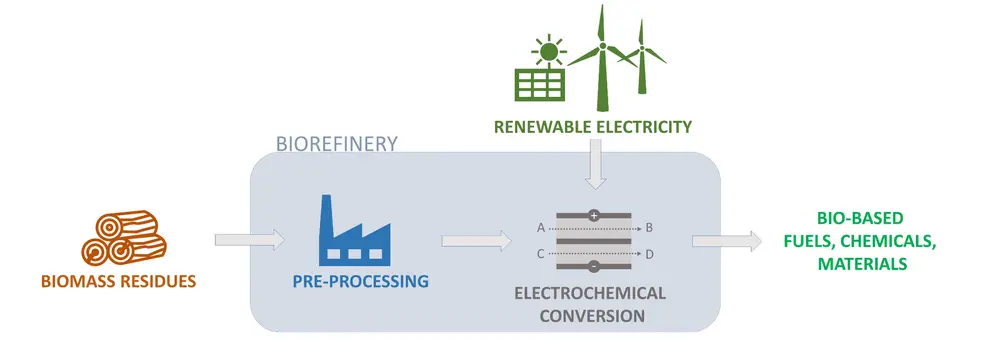

The ambition to eliminate consumption of fossil based resources coupled with rapidly growing availability of renewable electricity raises interest into the development of electrochemical production methods for fuels, chemical building blocks and materials. Electrosynthesis has the potential to utilize sustainable energy and resources efficiently, eliminate the use of toxic solvents and minimize waste and carbon footprint of the production. Next to this, electrosynthesis satisfies at least 9 of the 12 postulates of sustainable or green chemistry.

potential of Electrochemical conversion

For the production of biomass derived chemicals, the use of electrochemical conversions has multiple advantages over using traditional methods. This includes the possibility of directly processing aqueous biomass feedstocks, the generation of oxidants or reducing agents without external reagents required (avoiding waste), operation at near ambient conditions, allowing a smaller decentralized production scale and intermittent processing with reduced reliance on heat recovery. In the near future the benefits of electrochemical transformations will favor biorefining with renewable electricity.

At TNO, within the business driven Voltachem shared innovation program, in the Power-2-Chemicals development line many research projects are running to develop electrochemical production routes and assist the chemical industry to make a step forward towards future implementation. The development of the Power-2-Chemicals technologies target a decrease in the capital costs via process intensification as well as an enhancement of process efficiencies and selectivities, leading to a reduction of the production costs of renewable fuels and chemicals.

A great example project in the Power-2-Chemicals line demonstrating a step forward of the technology readiness level is the Horizon-2020 sponsored PERFORM project, which aims at the development and demonstration of electrochemical production processes of bio-based chemicals produced from biomass at TRL 5-6 and shows the potential for selective and efficient large scale production.

EU Perform project

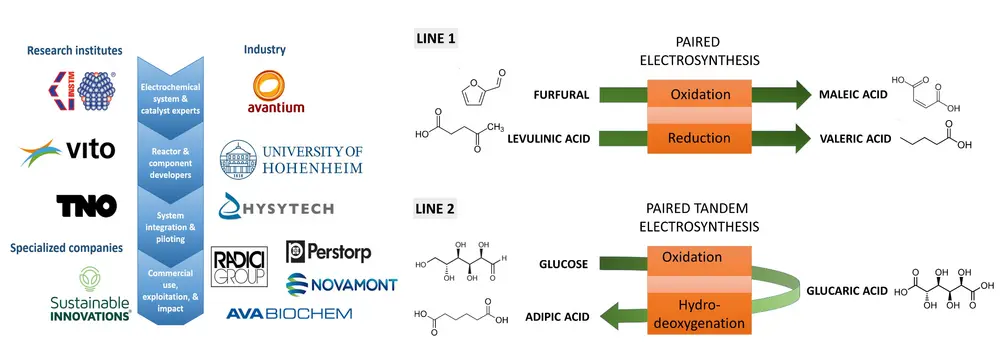

A multinational European consortium led by TNO (The Netherlands) and formed by VITO (Belgium), Avantium (The Netherlands), INSTM (Italy), Hysytech (Italy), Sustainable Innovations (Spain), Perstorp (Sweden), University of Hohenheim (Germany), Radici Chimica (Italy), AVA Biochem (Switzerland) and Novamont (Italy) is developing novel electrochemical production processes for the production of biomass derived bio-based carboxylic acids: maleic, valeric, glucaric and adipic acids in two demonstration show cases. The first showcase, development Line 1, covers electrochemical production of maleic acid from furfural paired with the production of valeric acid from levulinic acid; while the second showcase, development Line 2, deals with - adipic acid production from glucose.

As a result, within the project a flexible PowerPlatform pilot plant will be constructed in order to demonstrate feasibility of the developed technologies and innovations, that will lead to the implementation of electrochemical production methods for a more efficient and sustainable production. This PowerPlatform pilot plant consists of the electrochemical unit with reactor stack and additionally selected downstream processing units suitable for separation and purification of the target molecules. The PowerPlatform will continue its service after the project finalization, to allow future tests onsite.

The overall approach is characterized by the development of four key technologies that will be integrated in the modular and flexible PowerPlatform:

• Paired electro-synthesis

• Electrochemical process intensification

• Upscaling of electrode production

• Integrated electrochemical process system design

The project addresses: feedstock pre-treatment, optimization and scale up of paired electrochemical production, and related downstream processing, operation with intermittent electricity supply.

The production of bio-based maleic and valeric acids has never been demonstrated at this performance and scale

Current status & recent developments

This year, the 3rd year of the four year project started and the consortium already achieved several important milestones:

• Feedstock pre-treatment technologies developed

• Electrolysis optimization with selectivities and efficiencies towards target molecules >80%

• Process designed and downstream technologies optimized at lab scale

• A 0.1 m2 modular electrochemical reactor designed, constructed, and tested. Attainable productivities of 50 – 100 g/h.

For both demonstration showcases processes have been designed. The “Demeter-1”, a 0.1 m2, modular electrochemical flow reactor, allows testing of various electrochemical conversion reactions on various electrode types (plate, mesh and porous 3D electrodes). This reactor is an important stepping stone of the electrochemical reactor optimization phase, prior to further scale up towards industrial dimensions of 1.0-2.5 m2 electrode surface area. TNO constructed a semi-automated ambient electrolysis test station to test and optimize the reactor. Testing activities are still ongoing. The current scale allows production of industrial samples up to 50 g/h maleic acid and 100 g/h valeric acid from biobased feedstock (furfural and levulinic acid) to be tested by the end user partners in the project.

In parallel, the consortium has achieved significant progress in designing the process for both lines and validating them, using dedicated downstream processing technologies to achieve target productivity and purity of the products. Downstream technologies such as crystallization, antisolvent precipitation, liquid-liquid extraction, distillation, electro-dialysis, nano-filtration have been tested and optimized on a lab-scale for the production of maleic, valeric, glucaric and adipic acids. For example, for valeric and maleic acids, the proposed DSP strategy allowed separation yields of >80% with a purity of >95%. Additionally, proof of principle for some of the pilot-scale DSP equipment, with flowrates of 1-10 L/h, has been reached. This project thus presents a breakthrough, because the production of bio-based maleic and valeric acids has never been demonstrated at this performance and scale.

The project is a breakthrough in the field of electrochemical production of bio-based chemicals. The next step in the project is the construction of the Pilot PowerPlatform with a stacked reactor of 1 m2 and selected bench scale downstream processing units, suitable for both showcases, including equipment such as crystallizers, extraction units, distillation columns, filtration units and more. A continuous process demonstration at TRL 5-6 is aimed for, with a PERFORM Power Platform test campaign of at least 200 hours for both the conversion and integrated downstream processing.

This project is an important step forward towards implementing novel green chemical production routes

Conclusion

Considering the immaturity of electrochemical production of biomass derived chemicals, there is an urgent need for rapid development and deployment of these technologies if they are to play a role in mitigation of global carbon emissions and reaching goals for climate-neutrality by 2050. The EU PERFORM project, is a unique project which is demonstrating high potential of electrochemical transformations for a sustainable production of bio-based chemicals and will make a significant contribution towards implementation of the electrochemical production technologies. The project is on its way to demonstrate the electrochemical production of carboxylic acids (maleic, valeric, glucaric, adipic acids) at TRL5-6. This is an important step forward towards implementing novel green chemical production routes.

ABOUT THE AUTHORS

Roman Latsuzbaia is a research scientist at TNO and technically responsible for the electrochemical reactor and process development activities within various projects in VoltaChem Power-2-Chemicals line. In his role as technical lead he combines developments in the electrochemistry domain with electrochemical reactor engineering, scale-up and process development.

Earl Goetheer is a principal scientist process technology at TNO, a part-time professor electrochemical CO2 transformation at TU Delft and scientifically responsible for the Power-2-Chemicals research line within VoltaChem. He was the originator of the direct carbon capture-conversion idea by combining his large experience in carbon capture and utilization with recent developments in power-to- X using electrochemistry.

Erwin Giling is a project and program manager in the Power-2-Chemicals research line of VoltaChem with more than a decade of experience in developing pilots and leading projects in the fields of CO2 capture and electrochemical conversions. Erwin is a coordinator of the PERFORM project.

Acknowledgements